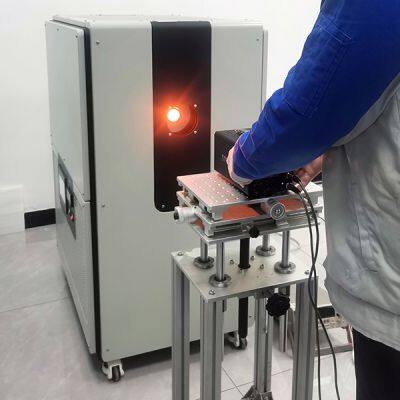

Application of surface blackbody radiation sources in various fields

1.Calibration and verification of infrared temperature measurement system:

Core application: This is the most extensive and important application of surface blackbody. All non-contact infrared temperature measurement equipment (spot pyrometers, thermal imagers) need to be calibrated regularly to ensure the accuracy of their measurement results.

Working principle: Aim the infrared temperature measurement device at the radiating surface of the surface blackbody with a known temperature. The device measures the intensity of the received radiation and converts it into a temperature reading. By comparing the device reading with the actual temperature set by the blackbody, the device error can be determined and calibrated (adjust offset, gain, etc.).

Advantages: Provides an absolute temperature reference, and the calibration process is direct and reliable. Surface source blackbody is particularly suitable for calibrating thermal imagers because it can cover the entire field of view of the thermal imager or a specific area, providing a uniform temperature field.

Scenarios: Online thermometer calibration in factory process control, laboratory verification of portable thermometers, production calibration of thermal imager manufacturers, and regular calibration by users.

2.Calibration and performance testing of thermal imaging (infrared thermal imager) systems:

Key roles: The core function of a thermal imager is to generate a temperature distribution image (thermal map) of the target being measured. Its key performance indicators such as accuracy, temperature resolution, uniformity, and noise level need to be tested and calibrated using surface source blackbody.

Application:

Uniformity calibration: Let the thermal imager observe a large area surface source blackbody set at a constant temperature (such as ambient temperature). Ideally, the entire image should show uniform brightness (temperature). Any non-uniformity (bad spots, stripes) can be detected and corrected.

Temperature calibration/two-point correction: Use at least two surface source black bodies with different temperatures (usually one close to the lower limit of the low temperature measurement range and one close to the upper limit). The thermal imager collects image data at these two temperatures respectively, and establishes an accurate mapping relationship (correction curve) between its detector response (grayscale value) and the actual temperature.

Scenarios: Thermal imager R&D, production and manufacturing, metrology agency verification, user routine maintenance and calibration (especially for high-precision or scientific research-level thermal imagers), security monitoring thermal imager performance verification.

3.Testing and characterization of infrared sensors and detectors:

Application: During the R&D and production stages, the performance parameters of infrared detectors (such as uncooled microbolometers and cooled photodetectors) are evaluated, including:

Responsivity: The size of the electrical signal generated per unit of radiation power.

Noise equivalent power: The minimum radiation power that the detector can detect (signal-to-noise ratio = 1).

Detection rate: A comprehensive indicator that measures the detector's ability to detect weak signals.

Response time: How quickly the detector reacts to changes in radiation.

Linearity: The degree of linear relationship between the output signal and the input radiation power.

Spectral response: The detector's ability to respond to radiation of different wavelengths (needs to be combined with a monochromator or filter).

Working principle: Aim the detector to be tested at a surface source black body. By precisely changing the temperature of the black body (thereby changing the radiation intensity) or using a modulator to modulate the radiation of the black body, measure the detector's output signal, and then calculate the above parameters.

4.Calibration of remote sensing instruments:

Spaceborne/airborne infrared remote sensing: Infrared sensors on satellites or aircraft (used for meteorological observation, environmental monitoring, resource exploration, military reconnaissance, etc.) need to be strictly calibrated on the ground before launch, and regularly calibrated on-orbit/during flight to eliminate instrument drift and environmental effects.

Application:

Laboratory calibration: In a vacuum tank simulating space or high-altitude environment, a precision-controlled surface black body is used as a standard radiation source to calibrate the entire machine or key components.

On-orbit/on-flight black body calibration: Many remote sensing instruments have surface black body sources installed inside or pointing to the outside. The instrument periodically switches the field of view to these black bodies of known temperature for measurement, providing a reference point for subsequent processing of real earth scene data and achieving absolute calibration of radiation.

5.Calibration of medical temperature measurement equipment:

Application: Calibrate non-contact medical thermometers, such as forehead thermometers and ear thermometers (whose probes actually measure the infrared radiation of the ear canal tympanic membrane). Although ear thermometers usually use more precise cavity black bodies to simulate tympanic membrane radiation, surface source black bodies can also be used for some principle verification or calibration links with slightly lower requirements. For batch calibration of forehead thermometers for screening, surface source black bodies are commonly used tools.

Requirements: Medical calibration has very high requirements for temperature stability, uniformity and accuracy of black bodies (usually ±0.1°C or higher accuracy around human body temperature of 37°C).

6.Emerging fields:

Autonomous driving: Used to calibrate on-board infrared thermal imagers (for night vision, pedestrian/animal detection).

Lidar: Some lidar systems (especially those detecting mid- and far-infrared wavelengths) may use blackbody sources for internal calibration or performance testing.

Process monitoring: In some complex industrial processes that require continuous monitoring of infrared sensor reference points, fixed-mounted surface source blackbodies can be used as online calibration references.

High emissivity: Close to an ideal blackbody, the radiation characteristics are predictable and stable.

Uniformity: The surface temperature is evenly distributed, providing a stable radiation field, which is particularly suitable for thermal imager calibration.

Precise temperature control: High temperature stability, small uncertainty, and reliable reference temperature.

Flexible size and shape: Surface sources of different sizes (from a few centimeters to more than one meter) and shapes (square, round) can be customized according to application requirements.

Portability: Compared with large cavity blackbodies, many surface blackbodies are designed to be easily carried to the field for calibration.

Wide temperature range: Modern surface blackbodies can cover a temperature range from below ambient temperature (using a refrigerator) to well above 1000°C.

Surface blackbody radiation sources are indispensable metrological reference instruments for modern infrared technology. It is like an "optical temperature ruler", providing accurate, reliable, and traceable calibration references for all equipment that relies on infrared radiation for measurement (infrared thermometers, thermal imagers, infrared detectors, remote sensors), ensuring the accuracy and credibility of the measurement results of these devices. From industrial production quality control, equipment status monitoring, scientific research to meteorological satellite observations, medical diagnosis and security monitoring, its applications have penetrated into many key areas related to efficiency, safety and technological progress.

Recently Posted

-

How do you calibrate an infrared thermometer?

December 25, 2025How to calibrate an infrared thermometer?I. Calibration can be performed using a blackbody radiation source and a standard thermoc Read More

Read More -

The main force of China's thermal metrology team--Taian Demei Electromechanical Equipment Co.,Ltd.

December 13, 2025Taian Demei Electromechanical Equipment Co., Ltd., established in 2012 with a registered capital of 10 million RMB, is located at Read More

Read More -

Brief information about metrology related to temperature and humidity calibration chambers.

December 11, 2025Temperature and humidity sensors have achieved widespread technological application today. Indoor environments, industrial product Read More

Read More -

Precautions and temperature settings for purchasing blackbody radiation sources

December 10, 2025I. Unpacking the Blackbody Radiation SourcesCarefully inspect the surface of the blackbody radiation sources upon unpacking, as da Read More

Read More